Tyres are an essential product that we need to function as a society, they are used to transport everything from people to food. Even as we look to decarbonise our transport network and embrace new technology like electric vehicles, we still need tyres. So, developing, exploring, and adopting ways to extend the life of tyres and the materials they are made from, is essential for the development of Australia’s circular economy.

Essential resources

There’s certainly no shortage of this rubber resource, with 56 million passenger equivalent tyres reaching their end-of-life each year in Australia. But what’s so special about these black rubber rings we’re seemingly taking for granted?

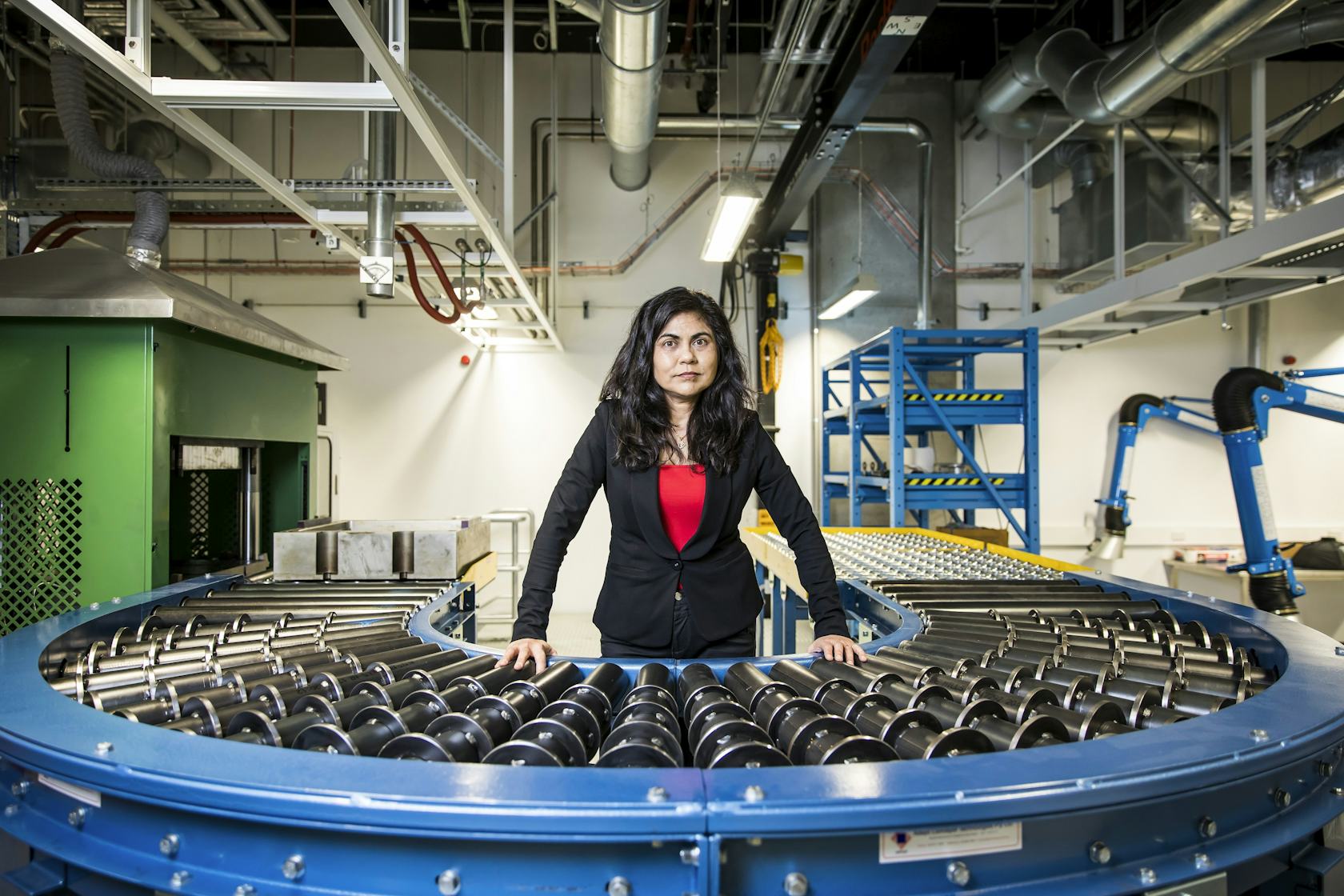

For Professor Veena Sahajwalla, Director of the Centre for Sustainable Materials Research and Technology (SMaRT) at the University of New South Wales, tyres are much more than waste. Professor Sahajwalla has developed technology that decarbonises steelmaking by replacing coal and coke with waste tyres. The process unlocks carbon and hydrogen from the tyres, creating a raw material ‘feedstock’ of hydrogen and solid carbon.

“Recycled tyres? We couldn’t ask for anything better! From forklifts to wheelchairs, tyres are an essential component in every community. Our technology takes rubber particles and injects them into Electric Arc Furnace (EAF) steel making process. This injection of rubber into molten slag creates reactions that ‘liberate’ the hydrogen and solid-carbon components of the rubber which drives the iron oxide conversion required for steel making, making rubber a renewable resource. There really is no waste!”

Professor Veena Sahajwalla's vision sees 'MICROfactories' set up in smaller communities to process recycled tyres for significant economical benefit.

The process is called Polymer Injection Technology (PIT) and the chemical reactions it creates in the steel making process replaces coke or coal in EAF steelmaking process, creating ‘Green Steel.’

“Essentially, we delve into the molecular level of waste materials and unlock their hidden value” explains Professor Veena.

“This allows us to transform and recycle tyres into even more valuable products. We will always need steel - so why not connect them all as part of an essential supply chain? The question what it takes for the world to decarbonise will come down to thinking laterally like this.”

The polymer injection technology from the SMaRT centre is a potential powerhouse in the next generation of green materials. And to think, these tyres could have gone to landfill!

A rubber-conomy

Every community, in every city, in every country uses tyres. This vast geographical accessibility of used tyres gives opportunity for local communities to extract the valuable resources in them.

“By processing waste close to where it is consumed, we can create value where the used products are centralised and allow everyone to become part of the supply chain,” says Professor Sahajwalla.

“Those collecting tyres can set up MICROfactories able to process the materials using the technology to reuse the materials and create new market opportunities for green manufacturing.”

This type of localised processing could allow local economies to engage in what Professor Veena coins ‘microrecycling’, and the solid carbon produced from this reform process could be used for carbon-based products across a multitude of industries.

By normalising a ‘what if’ mentality where all our ‘waste’ materials have potential value, we could unlock new opportunities in local manufacturing across the country. From a global perspective, as well as developing the technology, Australia owns the IP and the patent with partners currently working to distribute around the world.

We can all contribute

An essential step is in the recovery of used tyres. Tyre Stewardship Australia (TSA) promotes product stewardship for end-of-life tyres.

Car owners have the choice to make a significant impact on the fate of their old tyres when they purchase new ones. TSA’s online tool 'My Tyres My Choice' supports car owners to harness their purchasing power, helping them find their local TSA accredited tyre retailers that are responsibly managing used tyres.

There are also sixteen tyre and auto brands voluntarily contributing to Australia’s Tyre Product Stewardship Scheme. These brands are committed to supporting sustainable outcomes and are taking responsibility for the tyres they sell into the Australia market. As such, ‘My Tyres My Choice’ gives car owners the opportunity to support better outcomes for their used tyres.

“By connecting car owners with TSA Accredited tyre retailers, we’re making it easier for people to use their purchasing power to support the responsible management of their used tyres. That’s the first important step towards getting used tyres recycled and repurposed into new, innovative, and valuable products and applications” says TSA CEO Lina Goodman.

“People are becoming more aware of what happens when they are finished with products like their tyres, and are feeling an increasing responsibility to make a choice, that supports more sustainable outcomes for the products they use when they reach end of life.”

In addition to promoting responsible management across the used tyre supply chain, TSA continues to invest in market development, supporting innovation and growth in the tyre recycling sector and manufacturing from tyre-derived material. TSA has committed more than $9 million to research, develop, test and commercialise innovations for end-of-life tyres in Australia in products such as better performing roads, pavements, concrete safety barriers and more.

Driving value into the future

We have long been making practical uses for used tyres. When tyres began to wear out in the early 20th century they were repurposed as footwear, garden containers, as makeshift parts for machinery and even reinforcing trenches in WWII.

Technology is making exciting advancements, and there is increasing demand to use recycled materials, including tyres, as a feedstock in the manufacturing of new products with increased performance and quality benefits for a range of industries and sectors.

As we move into a world of global sustainability reporting and increasing consumer awareness, businesses are being driven to demonstrate their environmental efforts, and in turn the circularity of products at their end-of-life will also move higher on the agenda.

“The ecosystem must show that every participant in the supply chain is committed to doing their bit. There cannot be someone going it’s ok I’ll take it to landfill and then it’s not my problem anymore. Everyone doing that extra bit, going above what would normally be done. This can be achieved with a collaborative network” concludes Professor Veena.

Tyres continue to play a key role in our society, and it doesn’t stop once they reach the end of their life. The resources recovered from used tyres have been proven to provide value and benefits to accelerating our circular economy, and the possibilities across industries and sectors are endless.

Learn more about a circular economy at the Australian Circular Economy (ACE) Hub, an online community that connects people and organisations to collaborate towards a circular economy.

Read more about the Polymer Injection Technology ('Green Steel') from the SMaRT Centre here.